Printing on Wood

Industrial wood printer

Production environments for wood products can be challenging. Typically dusty and subject to temperature extremes, these operations run nearly nonstop to deliver products to industries ranging from construction to furniture production.

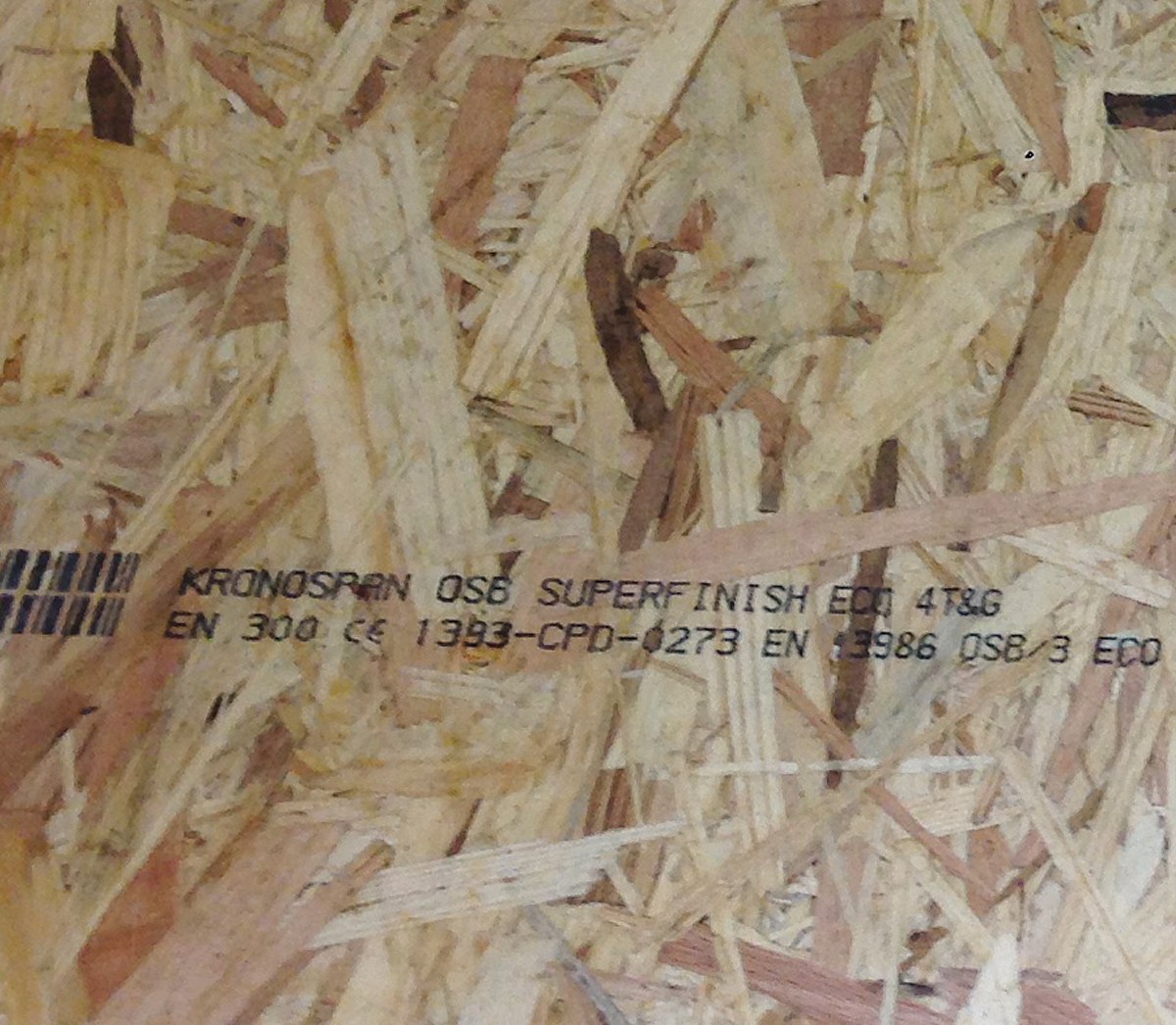

Printing dates, bar codes, moisture levels, panel grades, inspector ID, species, lot or batch numbers, and traceability data on wood under these conditions requires a robust, low- maintenance industrial wood printer.

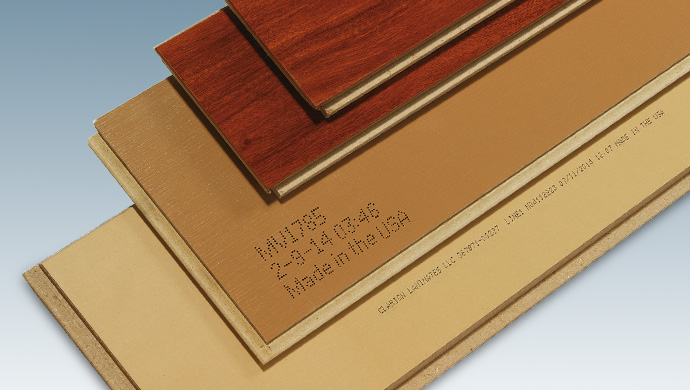

Videojet continuous inkjet (CIJ), laser marking systems, and thermal inkjet (TIJ) printers are designed to handle the operational intensity of wood production. These solutions are compatible with products ranging from raw lumber to coated or varnished wood for furnishings, flooring, and other finished items.

Unique demands of printing on wood

- Uptime is critically important for building material production lines. Equipment to print on wood must be dependable and easy to operate. Minimal maintenance is essential to eliminate downtime related to printer repairs and routine maintenance activities, such as replenishing ink.

- Challenges of irregular printing surfaces coupled with hot, dusty production environments can be addressed by rugged CIJ, TIJ, and LCM printers designed for printing on wood. They are well-suited to print crisp, consistent codes in these conditions.

- Incorrect codes on lumber and other wood products can be difficult to correct, leading to scrap and rework. Printers that limit operator intervention and eliminate data-entry errors are imperative.

Videojet expertise

For printing on wood, Videojet offers three printing/marking technologies along with specially formulated inks to meet unique application needs. To help ensure that the right code goes on the right product every time, Videojet printers incorporate Code Assurance capabilities using rules-based software, user-friendly interface and network communication.

Videojet continuous inkjet solutions

- Ink-based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics

- Variable throw distance allows for flexible printhead placement, helping reduce damage printhead damage when lumber surfaces are uneven.

- High-contrast ink options are available that help deliver clear, clean codes in white, yellow, black, blue, and red for high-visibility codes on dark surfaces.

Continuous inkjet (CIJ)

Videojet 1580 +

Videojet laser solutions

- In addition to ink-based solutions, printing on wood can be achieved with laser marking systems.

- Using no consumables, lasers can help to reduce a manufacturer’s environmental footprint.

- The complete line of Videojet CO2, fiber and UV laser marking systems includes a wide range of power and lens options.

Laser marking systems

Videojet 3350

Videojet thermal inkjet solutions

- Ink-based, non-contact printing uses heat and surface tension to apply codes onto wood

- Ideal for printing 2D and other high-resolution bar codes and logos

- Easy cartridge change-out provides a new printhead each time

Thermal inkjet (TIJ)

Videojet 8520

Applications

Resources

Infographic