Printing on Fruits and Vegetables

Fruit and vegetable packaging facilities are among the most demanding and varied production environments – from temperature and humidity extremes to moisture and dust. Production leaders need a coding and marking supplier that understands these challenges and can address an increasing variety of packaging formats. With the broadest technology offering in the industry, Videojet meets these challenges with an array of cost-effective, high uptime solutions.

Understanding the Challenges of Printing on Fruits and Vegetables

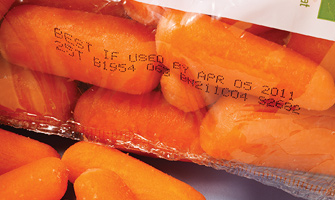

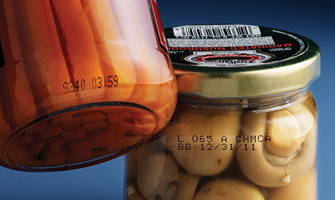

Printing on fruits and vegetables requires specialized equipment capable of handling unique production environments. These facilities often face extreme conditions such as fluctuating temperatures, high humidity levels, and exposure to moisture and dust. To maintain compliance with food safety regulations and ensure traceability, it’s essential to have reliable coding and marking solutions.

Videojet’s Advanced Solutions for Printing on Fruits and Vegetables

Videojet provides a comprehensive range of solutions designed specifically for printing on fruits and vegetables. Our technologies are engineered to deliver consistent performance even in the most challenging conditions. Here’s how Videojet stands out:

- Broad Technology Offering: Videojet offers the most extensive array of printing technologies in the industry, ensuring that we have the right solution for any packaging format and production environment.

- High Uptime Solutions: Our coding and marking systems are designed for maximum uptime, minimizing disruptions and ensuring continuous production.

- Cost-Effective Solutions: Videojet’s solutions are not only reliable but also cost-effective, helping you manage operational costs while maintaining high-quality printing standards.

Why Choose Videojet for Printing on Fruits and Vegetables?

- Reliability in Extreme Conditions: Videojet’s printers are built to withstand the harsh conditions of fruit and vegetable packaging facilities, ensuring reliable performance regardless of temperature, humidity, or dust levels.

- Versatile Application: Our solutions can handle various packaging formats, from individual fruits and vegetables to bulk packaging, ensuring clear and accurate printing every time.

- Compliance and Traceability: With Videojet’s advanced printing solutions, you can ensure that your products meet industry standards for traceability and food safety, protecting your brand and your customers.

Explore Videojet’s Solutions for Printing on Fruits and Vegetables

At Videojet, we understand the unique challenges faced by fruit and vegetable packaging facilities. Our dedicated team of experts is ready to help you find the perfect coding and marking solution for your needs. Contact us today to learn more about our advanced solutions for printing on fruits and vegetables and discover how we can help you achieve your production goals.

How Can I get a Videojet? : Ready to enhance your fruit and vegetable packaging process? Contact Videojet today to explore our comprehensive range of printing solutions and see how we can support your production needs.

- Applications

- Documents

Engineered for high uptime even in tough environments:

- CleanFlow™ printhead technology resists ink and dust build-up that can cause ordinary inkjet printers to shut down

- Withstand tough conditions with Videojet’s robust lasers and fume extraction systems

- Operate at temperatures down to 2°C/35°F with the DataFlex® Thermal Transfer Overprinter and selected ribbons

- Protection from dust and water with IP65 environmental protection on select Videojet printers

- Specialty inks designed by industry leading chemists including thermochromic inks for retort applications and condensation resistant inks

- Manage service and maintenance costs with a variety of Videojet service offerings designed to help with uptime and cost predictability

Printers designed to be inherently simple to keep operators focused on production:

- Visual, menu-driven interface enables easy operation and message updates

- Technology specific enhancements to aid operator workflow including, for example, automated setup and calibration on Videojet CIJ printers

- Easily adjustable printers to facilitate line changeover

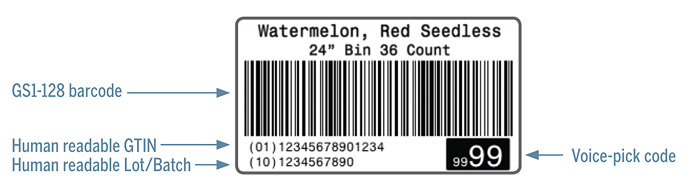

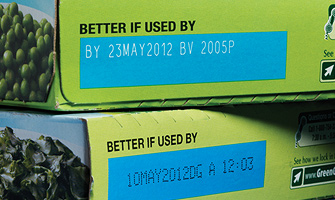

Videojet can help you implement traceability solutions including Produce Traceability Initiative (PTI) milestones with our inline case printing solutions:

- Videojet offers both High Resolution Large Character inkjet Systems and Label Printer Applicators for case coding applications for PTI

- Videojet can work directly with your team to help accomplish select elements of the seven milestones outlined by the PTI action plan

Paperboard Cartons, Cups, Sleeves and Tubs

Corrugate Cases and Shrink and Stretch Wrap