High-Quality Thermal Transfer Overprinters for Flexible Packaging and Labels

Videojet’s Thermal Transfer Overprinters (TTO) are the ideal solution for printing variable content with precision and efficiency. Designed to meet the demands of modern production lines, these printers deliver high-resolution printing on flexible packaging, films, and labels while keeping downtime and production costs to a minimum.

Key Features of Thermal Transfer Overprinters

- Cost-Effective Operation: Minimize waste with advanced ribbon-saving technology and optimize your production costs.

- Versatile Printing Options: Easily print simple date and time codes, complex regulatory codes, ingredient lists, and marketing information.

- High-Resolution Printing: Achieve crisp, professional-quality images and text for enhanced product presentation and compliance.

- Reduced Downtime: With seamless integration and efficient changeover processes, Videojet TTO printers keep your production lines running at peak performance.

Videojet TTO printers

Thermal transfer overprinter (TTO)

Videojet DataFlex 6530 & 6330

Thermal transfer overprinter (TTO)

Videojet DataFlex 6230

Applications

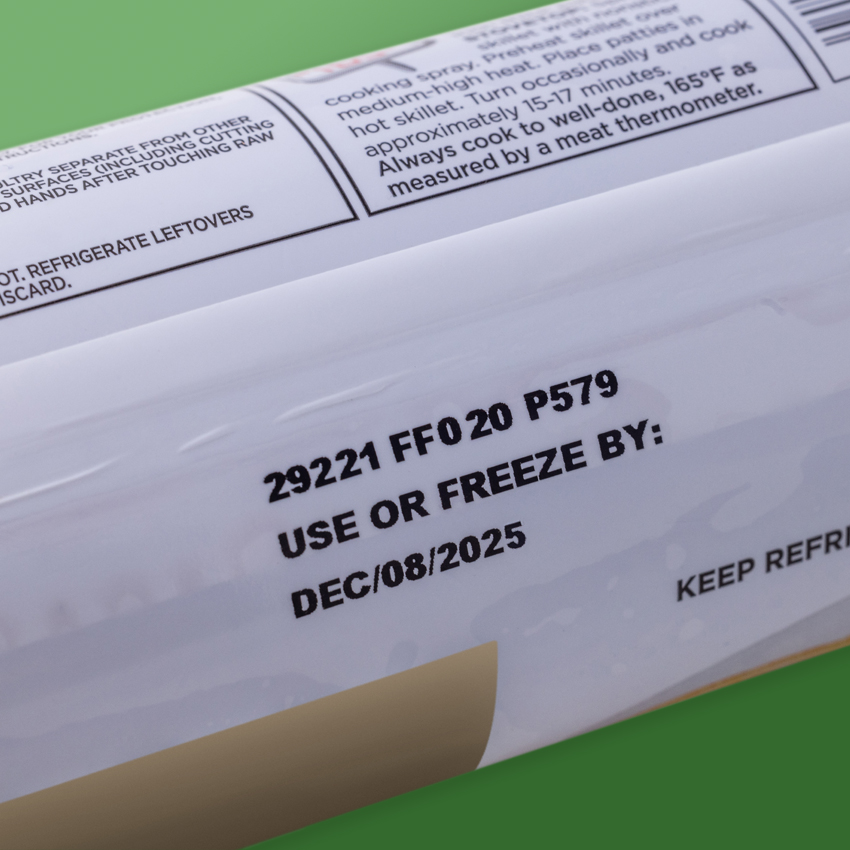

Thermal transfer overprinters are used for high-speed printing on flexible packaging, labels, and tags. They provide durable, high-quality printing of batch codes, expiration dates, barcodes, and logos, making them ideal for the food, pharmaceuticals, and consumer goods industries. TTO’s ability to print on various substrates enhances versatility in packaging operations.

FAQs

A thermal transfer overprinter is a printing device that uses heat to transfer ink from a ribbon onto packaging materials, such as flexible films. The process involves a thermal print head that applies heat to the ribbon and then melts the ink and transfers it onto the substrate. TTOs are commonly used for high-speed printing of variable information like barcodes, expiration dates, and lot numbers on flexible packaging.

Thermal Transfer Overprinters (TTO) are advanced printing devices that use heat and ribbon technology to print high-resolution variable content, such as date codes, barcodes, and ingredient lists, onto flexible packaging, films, and labels. They are widely used for precision printing in industries requiring compliance and traceability.

TTO printers offer several key advantages:

High-resolution printing for sharp and professional results.

Reduced downtime with efficient changeover processes.

Cost savings through advanced ribbon-saving technology.

Compatibility with various substrates, including flexible films and foils.

TTO printers are essential for industries such as:

Food and Beverage: For printing expiration dates, batch numbers, and ingredient details.

Pharmaceuticals: For regulatory codes, barcodes, and lot numbers.

Cosmetics and Personal Care: For branding, product descriptions, and traceability.

Yes, Videojet’s Thermal Transfer Overprinters are designed for high-speed environments. They provide reliable and consistent printing performance even on fast-moving production lines, ensuring minimal disruptions and maximum productivity.

TTO printers can print on a wide range of materials, including flexible packaging, labels, films, and foils. This versatility makes them suitable for various packaging formats used across industries.