Introduction

In today’s dynamic packaging industry, cartoning applications play a pivotal role in enhancing efficiency, product safety, and brand presentation. These applications refer to the integration of packaging machines, printers, and labeling systems to form, fill, and seal cartons.

At Videojet, we support UAE manufacturers with tailored solutions that ensure compliance, traceability, and high-speed productivity across various industries — from pharmaceuticals and food to cosmetics and consumer goods.

Understanding Cartoning Applications in Packaging

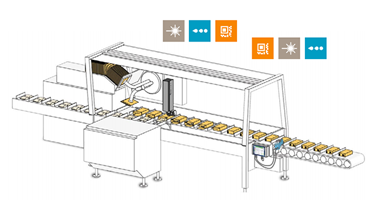

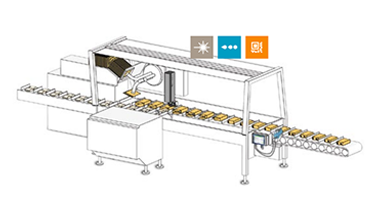

Cartoning applications involve multiple stages of the packaging process, including:

- Carton erecting (forming)

- Product insertion (manual or automatic)

- Coding or marking (batch numbers, expiry dates, barcodes)

- Carton sealing (glue or tuck-in)

- Labeling or tamper-proof application

Modern cartoning machines demand flexible coding solutions that integrate seamlessly into the production line, especially in high-speed environments common in UAE factories.

Cartoning Process Overview

- Primary Packaging: Inserting products such as blister packs, tubes, or sachets into individual cartons.

- Secondary Coding: Adding legible and permanent codes to cartons for product traceability.

- Tertiary Packaging Integration: Aligning with case packing and palletizing for distribution readiness.

Benefits of Cartoning Applications

- Improved line efficiency through automation

- Consistent and legible code placement on each carton

- Flexible configurations for horizontal or vertical machines

- Reduced downtime with durable printer integration

- Support for various shapes and carton sizes

Applications in UAE Industries

Cartoning applications are widely used in:

- Food & Beverage: For carton packaging of cereals, snacks, or beverages

- Pharmaceuticals: For pill boxes, vials, and tamper-proof labeling

- Cosmetics & Personal Care: For tube, jar, or bottle packaging

- Retail & E-commerce: For automation of product grouping and box coding

Related Articles

Suggested Solutions