Semi-Automatic Cartoning Machines are an ideal solution for manufacturers seeking a balance between automation and manual control. In these systems—whether vertical or horizontal—the carton loading process is manually operated. The operator inserts the product into the carton, which is then processed for sealing or further labeling.

This type of setup is common in UAE production lines where customized or irregular product shapes require human handling. By removing the automatic infeed system, these machines are simpler to operate and easier to maintain. However, it’s important to note that this also reduces overall production speed and throughput and may increase the number of operators needed on the line.

Semi-Automatic vs. Automatic Cartoning Machines

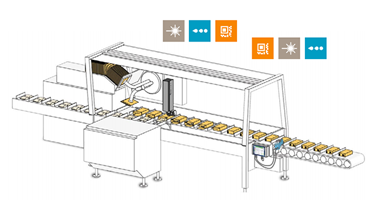

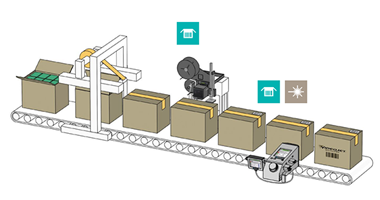

While semi-automatic systems rely on manual product insertion, automatic cartoning machines are designed to fully automate the process, improving speed and efficiency:

Types of Automatic Cartoning Machines

- Continuous Mode Cartoners

- Best suited for high-speed packaging lines

- Ideal for solid, regular-shaped products

- Product insertion is progressive and gentle

- Can handle speeds from 60 to over 400 cartons per minute

- Often integrated with automatic feeders, leaflet inserters, and coding systems like inkjet or laser marking

- Intermittent Mode Cartoners

- Operate in a start-stop motion

- Better suited for lower-speed lines or fragile, irregular products

- Still capable of integration with automatic code application and hot-melt sealing units

Both types of cartoners are built for side-load cartoning, where the product enters the carton laterally and the carton is sealed via flap insertion or hot-melt application.

Why Choose Semi-Automatic Cartoning Machines in the UAE?

- Lower initial investment cost compared to fully automated systems

- Ideal for startups and mid-scale packaging lines

- Great for low to medium volume runs

- Useful in packaging lines with frequent product or size changes

- Easier maintenance and simplified machine setup

- Manual product handling allows for delicate or irregular product packaging

Related Articles

Suggested Solutions