In a globalized market, product traceability is essential for ensuring transparency, safety, and compliance throughout the supply chain. From raw material sourcing to end-user delivery, Videojet provides cutting-edge track and trace coding solutions that enable real-time monitoring and documentation at every stage of the product journey.

What Is Product Traceability?

Product traceability is the process of identifying and recording a product’s path from origin to final destination. Using track and trace solutions, businesses can monitor manufacturing, packaging, shipping, and distribution events with coded data such as:

- Serial numbers

- Batch/lot codes

- Barcodes and QR codes

- Expiry and production dates

These marks ensure regulatory compliance, product recalls, and supply chain transparency — especially critical in pharmaceutical, food, and industrial manufacturing sectors.

Benefits of Product Traceability

✅ Enhanced product recalls with pinpoint accuracy

✅ Full transparency across global and regional supply chains

✅ Compliance with regulations such as GS1, EU FMD, and DSCSA

✅ Real-time insights for internal tracking systems

✅ Increased consumer trust and brand protection

Track and Trace Technologies

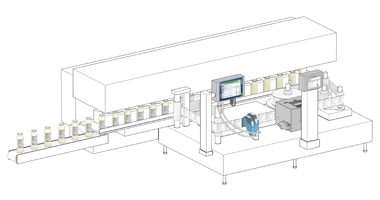

Videojet offers a comprehensive range of marking and coding technologies for product traceability:

- Inkjet Printers (CIJ/TIJ): Fast, non-contact printing for variable data

- Laser Marking Systems: Permanent coding with zero consumables

- Thermal Transfer Overprinters (TTO): Ideal for flexible packaging

- Serialization & Aggregation Software: Integrate with ERP and MES for full visibility

Each solution is built for high-speed production lines and challenging factory conditions.

Industries That Rely on Traceability

🔹 Pharmaceutical & Medical Devices: Comply with serialization laws and prevent counterfeit drugs

🔹 Food & Beverage: Ensure quality assurance and enable fast recalls

🔹 Cosmetics: Protect brand image through batch control and anti-tampering

🔹 Logistics & Warehousing: Track goods from factory floor to consumer doorstep

🔹 Automotive & Electronics: Enable part-level tracking across assembly stages