Videojet coding & marking solutions for packaging lines

A packaging line is a production line on which finished products are packaged to protect them during shipment and handling before use. The packaging material also provides a convenient surface to carry imprinted markings and codes that identify the product and enable regulators and purchasers to track its progress through shipping to the retailer or customer. In addition to packaging systems such as fillers, cartoners, case packers and palletizers, most packaging lines also incorporate coding and marking devices to apply the essential codes that meet regulatory requirements and enable accurate shipping traceability.

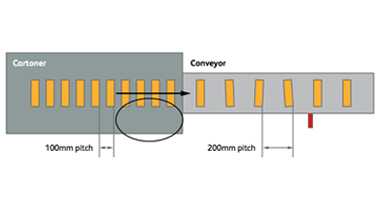

Space is often a challenge in packaging lines, and therefor most marking systems fit over or next to the primary line, rather than requiring to be inserted into the line itself. The marking systems are able to function effectively from these positions and add to line productivity by keeping the line compact and efficient.

The inkjet and laser coding machines that apply the needed codes also collect valuable production data summarizing the number and type products and packages being coded. Some coding systems also incorporate vision systems that capture and store visual images of the packages being coded, to ensure their readability.

Speed and efficient operation and low maintenance are essential for these marking systems. Any slowdown due to them will affect the productivity of the entire production/packaging operation. This why manufacturers of coding and marking machines such as Videojet design them to apply codes quickly and efficiently, in addition to producing codes that are permanent and readable.

Packaging lines use a wide range of packaging materials to package an extensive variety of products, from soft to hard, large to small, solid to flexible. To successfully mark these packaging materials, manufacturers have developed a broad selection of coding and marking machines, from laser printers and engravers to continuous inkjet and thermal inkjet printers. This enables companies to select marking systems that work most effectively with their unique packaging.