Harnessing resources and achieving optimal 2D code quality

Is your brand looking to adopt 2D codes for the GS1 Sunrise 2027 initiative? Unlike the existing EAN/UPC barcode on your packaging, these 2D codes can contain data such as batch/lot numbers and date codes, meaning they will need to be printed at the time of packaging. As a result, the responsibility for high-quality codes shifts from the material supplier to your packaging team.

The good news is that, if you have already invested in advanced coding equipment, you might be well-equipped to face the challenges associated with variable data printing including 2D code printing. Today’s smart printers and laser markers are engineered for this purpose, making 2D codes easily achievable.

There are several important factors to consider when getting ready to print GS1 codes or 2D codes with GS1 structures on your packaging lines:

- Make sure your print technology is well-matched to your application and production requirements.

- Ensure that the data you encode in the 2D codes matches the GS1 specification.

- Verify that your printed 2D codes meet or exceed the required quality level. See the section below regarding quality control.

The GS1 Sunrise 2027 initiative demands that printed 2D codes remain scannable from production to point-of-sale. Excellent print quality and durability, precise data accuracy, and consistent code reliability are crucial.

Data format

As part of the GS1 Sunrise 2027 initiative, GS1 codes and 2D codes with GS1 structures encode data utilizing GS1 Application Identifiers (AIs). An excellent source of information about AIs is the GS1 2D Barcodes Implementation Guide.

Depending on a brand’s needs, various AIs can be used. Some of the common identifiers employed in retail are:

- 01 – Global Trade Item Number (GTIN). This is always the 14-digit GTIN

- 10 – Batch or Lot Number

- 17 – Expiration Date YYMMDD

- 21 – Serial Number

All GS1 AIs are listed here: https://ref.gs1.org/ai/

Example encoding

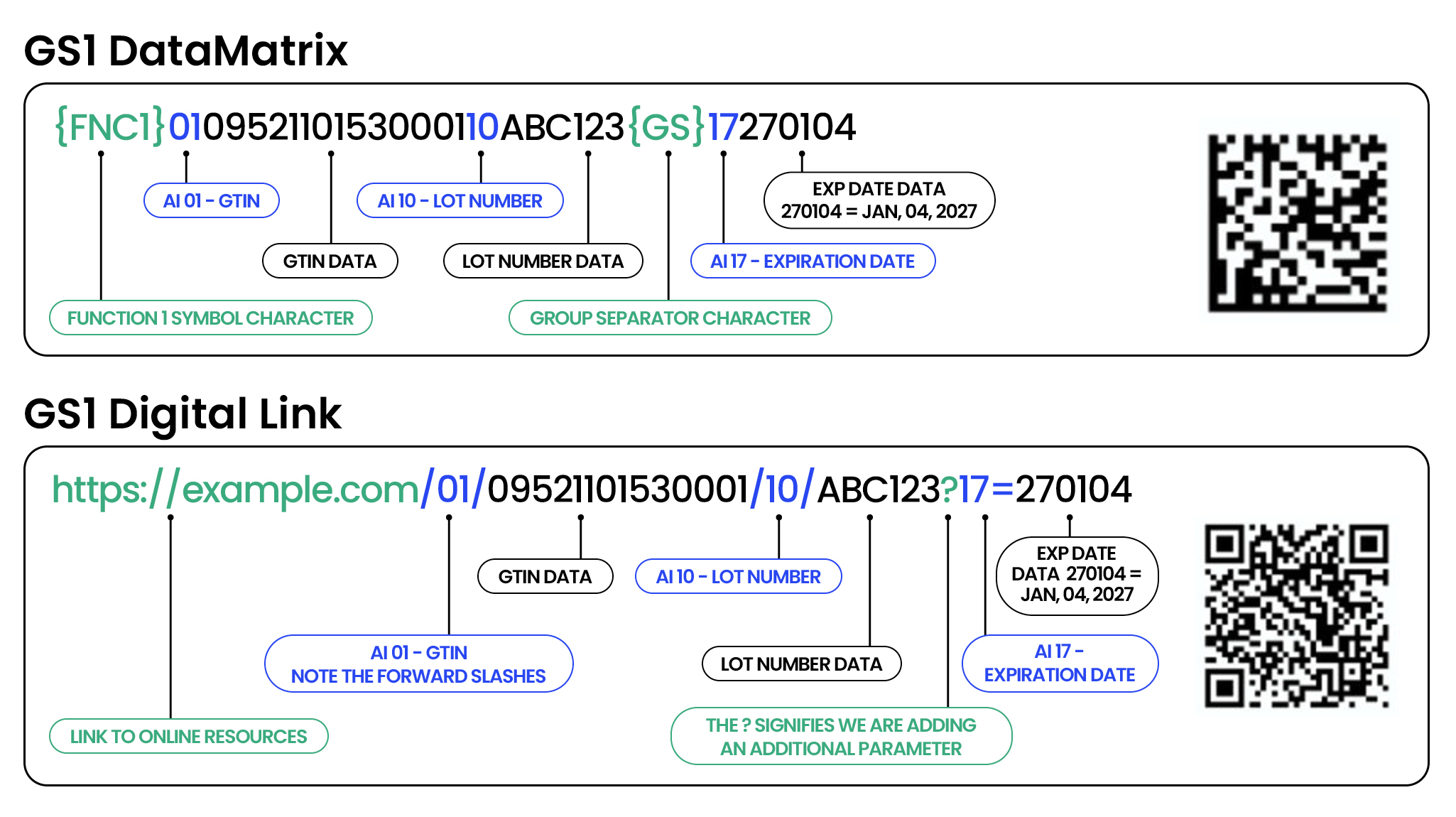

Two types of 2D codes can be used in Sunrise 2027: GS1 Digital Link in QR codes® and GS1 DataMatrix codes. While both can contain the same data using the GS1 Application Identifiers, they can only be used in the form of a GS1 Digital Link in the QR code. In this way, the QR code also provides a link to online resources that can include detailed nutrition information, recycling instructions, coupons, and more.

Examples of a product’s DataMatrix and QR code with the following parameters:

- GTIN: 09521101530001

- Lot or Batch Number: ABC123

- Expiration Date: 270104 – January 4, 2027

Validation of data

Validation is the process of inspecting the printed 2D code to ensure the information is encoded correctly. Scanners, ranging from fixed-position units to handheld devices and even smartphone apps, are used to perform this validation process. There are two primary inspections: checking the print quality of the code and verifying the accuracy of the embedded data.

- Code quality validation: This involves a visual inspection to ensure that the code is printed clearly and without defects. This is crucial for maintaining the code’s readability and making sure it can be scanned properly.

- Data accuracy validation: Following the quality inspection, scanners assess the code to confirm that the encoded data is correct and corresponds with the specific product information. This step is vital for capturing any errors in highly dynamic code printing.

Quality control

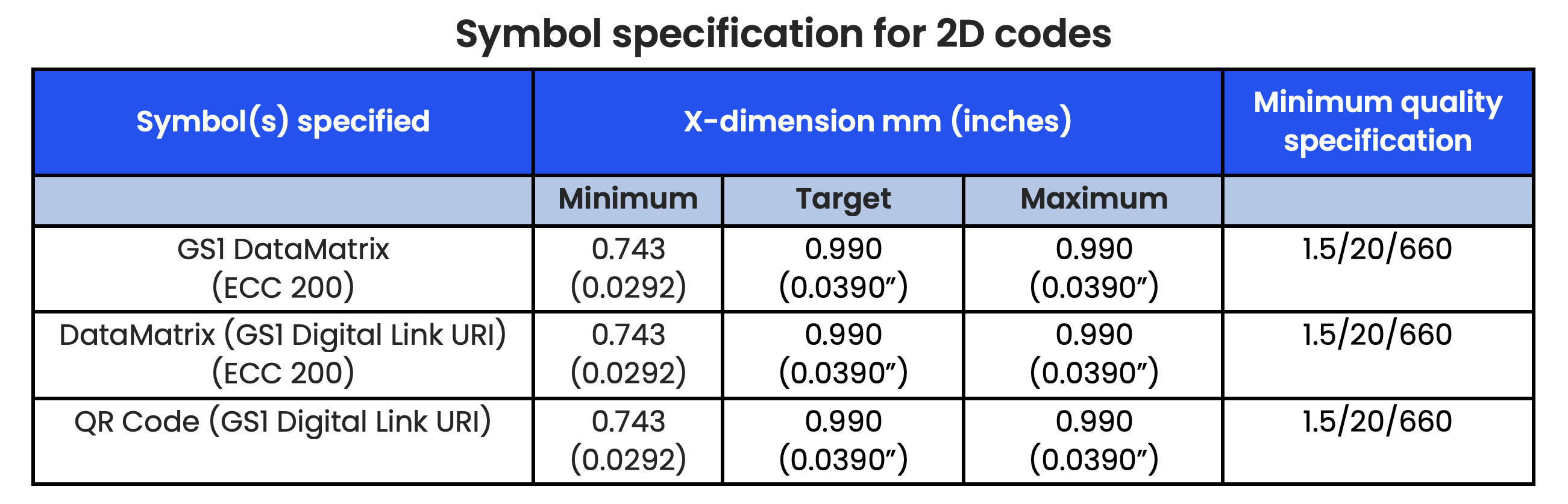

When you print a 2D code on your packaging, it is vital that every point-of-sale (POS), presentation (stand-mounted) scanner, and handheld device used in retail environments can successfully scan and decode it. To ensure this is achieved, GS1 specifies a particular quality level for 2D codes, as defined in the international standard ISO/IEC 15415.

The GS1 General Specification requires a minimum quality score of 1.5 (or C in the old ANSII grading system) when verifying the quality of DataMatrix and QR codes.

You can download the GS1 General specifications document here: https://www.gs1.org/standards/barcodes-epcrfid-id-keys/gs1-general-specifications

The ISO standard can be purchased here: https://www.iso.org/standard/76876.html

Verification of 2D code quality

Verification refers to the process of grading the quality and accuracy of a printed code. ISO/IEC 15415 is the standard for quality grading of 2D codes, while ISO/IEC 15416 is the standard for linear barcodes.

There are several versions of code verifier devices available for linear barcodes and 2D codes, including tabletop models for spot-checking codes and inline models that can verify codes on the packaging line.

Verifiers analyze several parameters, such as symbol contrast, edge determination, modulation, and quiet zones, and assign an overall quality grade ranging from 0.0 to 4.0, with 4.0 being the highest score available.

Code verification ensures printed codes meet the industry-specific quality requirements of GS1 (and other standards such as HIBCC) and also validates the data formatting to prevent scanning errors.

The verifier produces a results page for each code that it inspects, which can be saved as a reference to show the code quality and correctness in the event an issue occurs later.

Which print technology should be used for 2D codes?

The Videojet product portfolio includes a wide range of printing and marking solutions that produce clear, scannable 2D codes on just about every retail packaging type.

- Continuous Inkjet (CIJ): CIJ printers can provide excellent print quality for codes and text on various packaging materials. With fast-drying, highly durable inks, these printers can operate at the high output speeds needed for the most demanding applications.

Work with your Videojet to confirm CIJ technology meets all your requirements for 2D code quality and verification in your application.

- Thermal inkjet (TIJ): Offering high-resolution printing, TIJ technology can produce 2D codes and alphanumeric codes of exceptional quality on a wide range of packaging materials. With very low maintenance requirements and excellent uptime, TIJ printers are ideal for many applications.

A single TIJ printer, usually with a maximum print height of 12mm, can achieve GS1 DataMatrix codes. The printing of GS1 QR codes may be possible by stitching up to four printheads together. Testing is necessary to determine the ideal printer and printhead configuration.

- Laser marking systems: Featuring minimal maintenance requirements, CO2, fiber and UV laser systems are engineered to produce high-quality, permanent marks, even in harsh environments.

Marking with extremely high detail and resolution, lasers can produce scannable 2D codes, along with alphanumeric text, on a wide range of retail packaging materials, including plastic, glass, and paperboard. These permanent marks will not rub off as a product travels through the distribution chain. Select lasers can even mark on flexible films. Unlike other technologies, lasers do not require consumables like ink or ribbons.

Because different materials respond to laser marking in different ways, it is important to have your packaging substrates tested to determine the ideal laser for your application.

- Thermal transfer overprinters (TTO): TTO technology is excellent for printing high-quality barcodes, text, and images on flexible packaging and labels on both continuous and intermittent motion packaging equipment.

With a larger print area than the other coding technologies, TTO is highly versatile in the print formats it can handle.

To ensure success with 2D codes for GS1 Sunrise 2027, the key factors are data, quality, and printing.

Videojet is your partner for all aspects of the Sunrise initiative, so be sure to contact us when introducing these 2D codes to your packaging operations.

Additional reading:

Videojet: Sunrise 2027: 2D Code Revolution

Videojet: Printing Barcodes and 2D Codes

QR Code is a registered trademark of DENSO WAVE INCORPORATED.