Excellent mark quality and code permanence are key factors in quality assurance and traceability. Companies are faced with the challenge of finding effective marking solutions that not only guarantee readability and durability but also help reduce on-going costs associated with consumables while keeping maintenance efforts low. Here, laser technology comes into focus, as it meets these requirements and can even exceed them. This article highlights how laser marking has evolved into an efficient solution that can increase productivity while reducing operating costs.

Laser marking is versatile and efficient, and it stands out with its ability to deliver high-quality marking on various substrates and across different packaging sizes and shapes without the need for costly consumables. Depending on the application and material, there are several types of laser marking systems that can be used. Some of the most common are:

- Fiber lasers: Particularly efficient and suitable for metals, plastics, films and foils. They offer high-contrast marks and speed. Often used in product marking on plastics such as coffee capsules and bottle caps, as well as switches in cars, on metal and metal surfaces, including aluminum cans, and electronic components.

- CO2 lasers: Ideal for organic materials such as wood, paper, cardboard, textiles, and some plastics. Frequently used in the packaging industry for marking glass and plastic bottles, PET, cardboard boxes, folded cartons, and cables, and for labels used on primary packaging.

- UV lasers: Inducing photochemical changes to sensitive materials, UV lasers are optimal for marking glass, certain plastics, and flexible packaging like films and foils. The lasers require less power and therefore cause less thermal/heat-induced damage to the substrate. Often used on medical packaging and products, such as glass vials, plastic bottles, and caps (LDPE and HDPE).

Stay ahead with real-time updates on the latest news:

Take it easy (on maintenance)

Laser marking systems offer a range of benefits to streamline processes and boost productivity. Few touch points and ease of maintenance can significantly reduce the need for operator intervention compared to ink- and ribbon-based coding solutions. Since lasers only require fume extractor filter replacements and no other consumables, they offer high availability, as production can continue seamlessly without having to be stopped repeatedly. The low-maintenance operation of lasers not only enhances efficiency but also minimizes the likelihood of human error, leading to less scrap and material waste. Additionally, newer lasers with optimized power outputs help ensure that businesses can rely on their laser systems as long-term marking solutions with less downtime and reduced overall costs compared to many fluids-based technologies.

The latest innovations in laser marking technology are game changers for reducing setup times. For example, with Videojet SmartFocus™ technology, the laser automatically adjusts the focus distance to a distance predetermined during setup, accommodating different product sizes and substrates quickly and accurately. This time-saving feature helps ensure that production can proceed swiftly and seamlessly without compromising on quality. In addition, systems with access to remote support deliver timely alerts to prompt maintenance or service actions, helping to reduce unexpected downtime and enhance productivity.

Leave a permanent mark

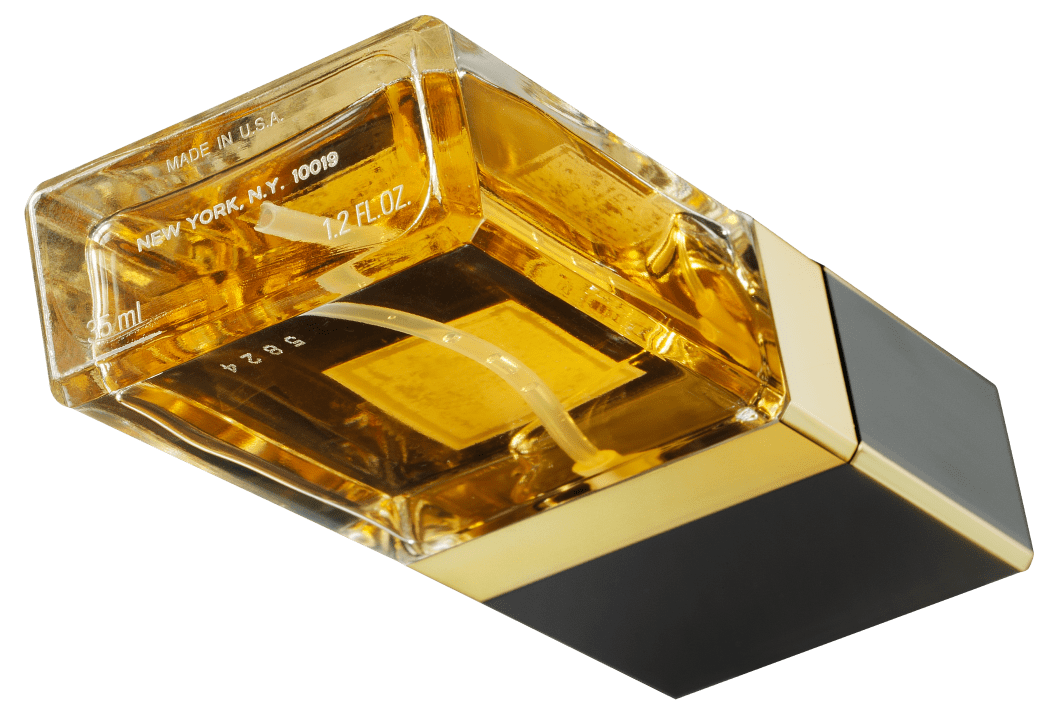

Counterfeiting and piracy can cause significant harm to manufacturers of luxury brands, perfumes, wines, pharmaceuticals, and many other products, leading to financial losses and a tarnished reputation. As a result, the permanence of product markings becomes a critical factor across various industries. These markings, including expiration dates and batch numbers on items such as food, beverages, and pharmaceuticals, must be secure against tampering to ensure consumer safety. Additionally, the ability to trace a product’s journey—from the origin of its components to its final distribution and location post-delivery—is a vital aspect of consumer protection. Traceability is essential for effective recall operations.

Permanent laser marking is resistant to chemicals, heat, and abrasion to ensure that critical information remains readable throughout the entire lifecycle of the product. It is durable and wear-resistant and offers versatility in code visibility. Depending on the surface texture, markings can be designed to provide high contrast for easy scanning or subtle contrast for aesthetic considerations. For instance, some manufacturers desire lighter markings on water bottles, perfumes, and alcohol bottles so the codes do not interfere with the product branding.

High speed and superior quality

Another significant benefit of laser marking, when compared to other coding and marking methods, is a very high marking speed. Some lasers can reach speeds of 2,000 characters per second or more, contributing to shorter production times and higher throughput. For example, in beverage production lines, up to 100,000 cans per hour can be marked. At the same time, laser systems deliver consistently exceptional marking quality and excellent readability of best-before dates, batch numbers, 2D codes, as well as logos, lettering, and serial numbers. Using laser marking systems, many compliance requirements can be met and penalties due to unreadable markings can be avoided.